A seismic digital transformation over the last decade has seen manufacturers optimize their entire operation—from forecasting and sourcing materials, to communicating with vendors, to improving plant performance using real-time data—well, that’s the dream anyway. For many manufacturers though, transformation efforts get stuck in ‘pilot purgatory’—caught between getting left behind or investing time and resources into extending inflexible off-the-shelf solutions or building from scratch.

But a third path exists: low-code solutions can empower manufacturing IT and engineering teams to digitize their toolset with custom software quickly. More modern and flexible than off-the-shelf tooling and spreadsheets, low-code platforms make it easier for manufacturers to modernize, with a lower barrier to entry than building from scratch. To understand why low-code bridges this gap so well, first let’s take a look at the common challenges manufacturers face with digital transformation.

Manufacturing businesses are pinning high hopes on the next industrial revolution—who wouldn’t want more efficient supply chains, improved productivity, and reduced factory waste?—but McKinsey reports that “only about 30 percent of companies are capturing value from Industry 4.0 solutions at scale today.” Industry 4.0 and the transformation afforded by integrating digital technology into manufacturing may be the promised land but if it feels out of reach, you’re not alone. A shortage of software development skills together with data silos and legacy tooling only widens the gap.

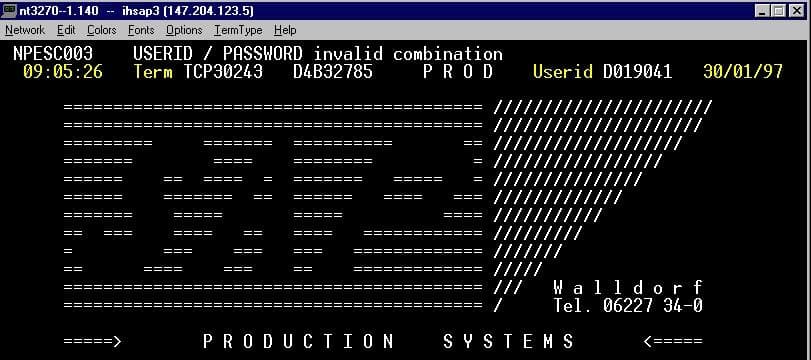

Even where processes have upgraded from paper, data remains fragmented across a sprawling toolchain of ERPs, spreadsheets, databases, data warehouses, and SaaS solutions (none of which play nicely together). Digital transformation promised seamless integration, but, in this state, teams often still have to work around errors and inefficiencies. Distributed teams across manufacturing sites, partners, and head offices may struggle to communicate without a single source of truth, and you can’t stream IoT sensor data anywhere if your systems aren’t cloud-ready.

The disparate toolset of ERPs, vertical software, and spreadsheets is holding manufacturers back. The inevitable data silos of a fragmented toolchain cause inefficiencies at every stage of a product’s lifecycle, from product development to repairs and accounting. We’ve seen countless examples:

- A food manufacturer couldn’t build dynamic forms incorporating data from CSVs, their ERP, and their databases, because SharePoint was deployed on-premises and couldn’t connect to their data.

- A technology company supporting FMCG found Oracle’s CSV-centric approach limiting, and needed better Google product integration.

- A scientific lab equipment manufacturer’s Oracle APEX-based inventory system for their Oracle database couldn’t integrate with their SQL Server-based systems, leading to data disconnection and manual processes.

cumbersome and expensive for IT teams to extend platforms like Microsoft Access, SharePoint, and Oracle VisualBuilder to support Industry 4.0 advancements. These time and resource burdens keep improvements like predictive maintenance or harnessing operational data out of reach.

Enterprise LCAPs like Mendix and Outsystems can be costly despite lagging behind more modern solutions with advanced capabilities. While industry-specific software often holds the promise of customized solutions, it later proves inflexible and unable to support nuanced use cases.

When existing tools fall short, teams often turn to the (next) lowest common denominator: spreadsheets. A fine interim workaround, spreadsheets quickly fall behind real-time data, become unwieldy at scale, and are error-prone due to manual entry.

If current solutions are letting manufacturers down, custom software development might seem like the obvious path towards a tailored solution. For most manufacturers, though, it represents stepping out into a whole new discipline for which you don’t have existing resources—which means hiring a dedicated team not just to build, but run and maintain. Solutions that seem simple enough to build can spiral quickly as your team gets bogged down with the various requirements that make building production-grade applications difficult and time consuming.

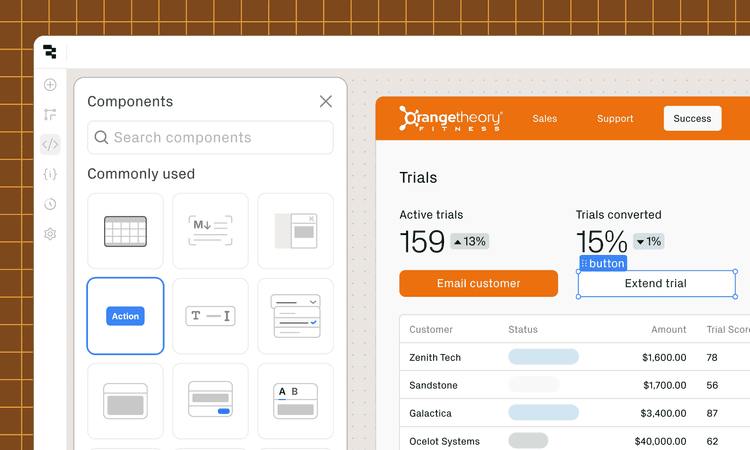

Today's low-code solutions are a more modern, flexible alternative to brittle enterprise software, inflexible vertical tools, and onerous self-built solutions. A low-code platform works with your existing systems to connect your data so you can build custom software quickly without the heavy lifting of a fully custom build.

With customizable building blocks available out-of-the-box, you won’t lose time deciding which web framework to use, how to implement data governance, grant role-based access controls, and more. Abstracting away the table-stakes requirements allows your team to move quickly or invest time in building features specific to your use case. A custom solution that integrates all your data also allows you to automate manual workflows, because data no longer slips through the cracks or requires a human to import it.

Choosing the right platform helps you to digitize your processes and your toolset—unlocking ongoing modernization efforts.

Business processes can’t rely on accurate inventory data if the underlying technology doesn’t support it. Adding fields, interfaces, and additional functionality to your ERP can be a costly and time-consuming process, impacting teams across the business, from the shop floor to finance. Inventory reconciliation becomes a manual process across disparate tools, leading to disjointed communication between teams, under- or overstocking, and fulfillment delays.

If your inventory data is spread across multiple sources of truth that don’t sync easily, a platform like Retool can provide a single pane of glass—able to read from and write to virtually any system of record. By uniting data silos you can ensure your inventory lists are always accurate, up to date, and easy to access. Better visibility into inventory levels also unlocks the next level: automated procurement and order management workflows that reduce errors and delays.

Fragmented data makes it difficult to identify trends and adapt to changing market conditions, while manual data entry is slow and prone to human error. Instead, uniting your data sources and automating data collection and processing frees up your teams to focus on analysis and strategic planning. Being able to accurately forecast production schedules—and adhere to them—means maximizing yield for your customers. Zeus also used Retool to build a data visualization app to track order timeliness and production schedules, replacing inefficient spreadsheet-based tracking.

Far too often, suppliers struggle to provide timely feedback on orders. Providing reasons for longer lead times, missing quantities and backfills, and requests for partial shipment all contribute to a better customer experience, but the current methods of emails and phone calls are too disconnected and cumbersome, and often require several attempts before successfully updating an order.

Onboarding and collaborating with suppliers and vendors is more efficient if you’re all on the same page with data that’s captured and monitored in real time. A portal that connects to your system of record enables visibility into supplier performance, order management, and chain-of-custody tracking for returns and repairs.

Without a centralized system to manage and track jobs, warehouse workers aren’t equipped to deliver work on time. Orders may be missed or delayed due to inaccurate inventory.

You can empower warehouse workers wherever they are by building mobile apps for connected warehouse management. Coordination and handoffs between design, engineering, and production teams are smoother with real-time apps that incorporate data from your PLM, MES, and other systems of record. No one needs to capture information on paper and manually enter it into a database. Retool Mobile speeds up development of mobile apps with prebuilt UI components like form inputs and validations, barcode scanning, and speech to text capabilities.

Low-code presents an opportunity for manufacturers to capture the rewards of Industry 4.0 without the significant upfront investment in customizing ERPs or building your own solution. The key to success is starting small with a manageable project and building on success there.

- Choose the right pilot project: A good proof of concept usually tackles an existing, inefficient process that’s causing friction for employees and/or suppliers, and that you believe can be solved with a custom interface connecting your systems of record. Any processes that require manual CSV uploads, email communication, multiple users modifying data in Excel, or using multiple tools for one job are good to explore.

- Start with your data: See what’s possible—connect Retool to your ERPs, databases, and APIs to see how easily you can integrate your data sources.

- Identify your development team: The advantage of a low-code solution like Retool is that while you can get under the hood to write code yourself, you don’t need a dedicated software engineering team to develop custom apps. The learning curve is lower as your team can write JavaScript, Python, and SQL instead of learning a proprietary language. And if you do need to bring in external developers, our Developer Network can connect you with the right people for the job.

A low-code solution makes digital transformation more accessible for manufacturers. Flexible enough to offer tailored solutions that work with your existing systems of record, but without the burden of building from scratch and maintaining bespoke software, Retool can free up your IT teams’ time and make your field workforce’s operations more efficient and accurate.

If that sounds good to you, let us show you to see how you can leave behind the data silos and level up your processes—set up a demo today.

Reader